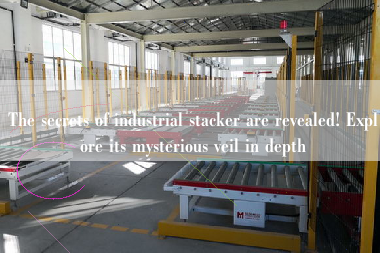

Uncover the secrets of nbsp;nbsp;nbsp; industrial palletizer! Explore its mysterious veil in depth

As an indispensable part of modern production process, nbsp;nbsp;nbsp; industrial palletizer plays a key role in many production fields. Industrial palletizer is a kind of high-tech automation equipment, which can automatically code, detect, classify and pack goods or needed items in the process of industrial production, and finally stack them in designated positions, which can greatly improve production efficiency and product quality. So in this article, let’s take a closer look at the mysteries behind this mysterious machine!

What are the applications of nbsp;nbsp;nbsp; industrial palletizer?

Nbsp;nbsp;nbsp; industrial palletizer is widely used in food, medicine, beverage, chemical, daily chemical and other industries. For example, the processes of elimination, sorting, palletizing and box sealing in industrial production can be completed automatically by industrial palletizers.

Why can nbsp;nbsp;nbsp; industrial palletizer replace the traditional mode of production?

The traditional mode of production of nbsp;nbsp;nbsp; often requires a lot of manual participation, the work efficiency is low, the quality is difficult to guarantee, and the work intensity and safety of personnel need to be considered. The industrial palletizer can automatically complete a series of actions, limit the interference of human factors, and effectively improve production efficiency and product quality.

What is the operation principle of nbsp;nbsp;nbsp; industrial palletizer?

The nbsp;nbsp;nbsp; industrial palletizer is designed to accommodate a variety of different product specifications and sizes, such as bottles, boxes, cans, etc. When these products arrive at the inspection station of the industrial palletizer, they will be automatically identified and sorted and arranged by means of push, rotation, abandonment, etc. After coding, classification and packaging, the products are automatically stacked in designated locations and neatly stacked in a column that can be easily containerized for transportation and storage.

Components of nbsp;nbsp;nbsp; industrial palletizer

The main components of nbsp;nbsp;nbsp; industrial palletizer include conveyor belt, identification system, palletizer, protective cover, distribution cabinet and so on, while its control system includes man-machine interface, PLC controller, motor driver, frequency converter and so on. The conveyor belt, identification system and palletizer are the main components of the industrial palletizer, which work together to automatically classify and stack the products from the production line.

Advantages of nbsp;nbsp;nbsp; industrial palletizer

Nbsp;nbsp;nbsp; industrial palletizer as an automatic mode of production, its advantage is not only to improve production efficiency and product quality, but also to reduce labor costs and labor costs. In addition, the industrial palletizer can ensure the neat stacking of items in the stacking process, reducing the risk of damage, improving the convenience of storage and saving storage space.

Nbsp;nbsp;nbsp; summary

Nbsp;nbsp;nbsp; to sum up, as a kind of high-tech automation equipment, industrial palletizer plays a more and more important role in modern industrial production. Through the exploration and use of industrial palletizers, manufacturers can easily achieve a multi-variety, small batch, high efficiency and high flexibility mode of production, improve production efficiency and product quality, and effectively promote the development of modern industry.