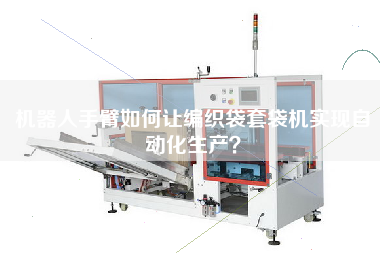

With the continuous development of society, automatic production has become the trend of modern industry. Woven bag bagging machine is a commonly used packaging equipment, but the traditional manual operation has been unable to meet the needs of modern industry. Therefore, the emergence of robot arm provides a new solution for the automatic production of woven bag bagging machine.

I. the basic principle of robot arm

Robot arm is a kind of automatic manipulator, which can simulate the movement of human arm and complete a variety of complex operations. It consists of a number of joints, each joint can rotate, stretch and other movements, so as to achieve the flexible operation of the robot arm.

2. Application of robot arm in woven bag bagging machine.

The robot arm can be used in conjunction with the braided bag bagging machine to realize the automatic production of woven bags. The specific steps are as follows:

1. Place the woven bag in the working area of the robot arm.

two。 According to the preset program, the robot arm picks up the woven bag and places it on the workbench of the bagging machine.

3. The bagging machine began to work and put the woven bag on the bag.

4. After the bagging is completed, the robot arm will remove the woven bag and place it in the finished product area.

Third, the advantages of robot arm in woven bag bagging machine.

1. Improve production efficiency: the robot arm can work 24 hours a day, which greatly improves the production efficiency.

two。 Reduce the labor cost: the traditional woven bag bagging machine needs manual operation, and the robot arm can replace the manual operation, which reduces the labor cost.

3. Improve the production quality: the precise operation of the robot arm can ensure the quality of the woven bag and reduce the error in production.

IV. Key points of robot arm selection

1. Load capacity: select the load capacity of the robot arm according to the size and weight of the woven bag.

two。 Working radius: select the working radius of the robot arm according to the size of the working area.

3. Precision requirements: select the accuracy grade of the robot arm according to the production requirements.

4. Price: choose the price of the robot arm according to the production cost and budget.

5. Conclusion

The emergence of robot arm provides a new solution for the automatic production of woven bag bagging machine. Through reasonable selection and operation, it can greatly improve the production efficiency and quality, reduce the production cost, and bring more profits for the enterprise.