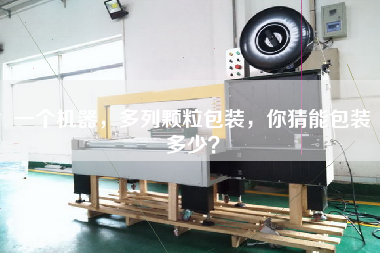

With the increasing demand for food safety and hygiene, the packaging machinery industry is also developing. In many packaging machinery, multi-row particle packaging machine is a very common machine. It can not only greatly improve the efficiency of packaging, but also ensure the quality and hygiene of packaging. So, one machine, multiple rows of particle packaging, guess how much can be packed?

First, the working principle of multi-row particle packaging machine

Multi-row particle packaging machine is a kind of automatic packaging machinery, which is mainly used for the packaging of granular goods. The working principle is as follows: the granular objects are put into the hopper, the granular objects are evenly distributed to each metering cup through a vibrator, and then the granular items in the metering cup are poured into the packaging bag, and finally the packaging bag is sealed by a heat sealing machine. The whole process is done automatically, and workers only need to put granular objects into the hopper.

Second, the advantages of multi-row particle packaging machine

Multi-row particle packaging machine has the following advantages:

1. High efficiency: multi-row particle packaging machine can pack multiple bags at the same time, which greatly improves the packaging efficiency.

two。 Precision: multi-row particle packaging machine uses metering cups to measure granular items, which can ensure the same number of granular items in each bag and avoid too much or too little.

3. Hygiene: the multi-row particle packaging machine is made of stainless steel, which is easy to clean and can ensure the hygiene of the packaging.

4. Save manpower: multi-row particle packaging machine is a kind of automatic packaging machinery, which only requires workers to put granular items into the hopper and does not need too much manpower.

Third, the packaging capacity of multi-row particle packaging machine

The packing capacity of multi-row particle packaging machine depends on many factors, such as the size, shape and weight of granular items, the size of packaging bags and so on. Take the general candy as an example, the packaging capacity of multi-row granule packaging machine is generally about 300-500 bags / minute. For some small granular items, such as pills, capsules, etc., the packaging capacity of multi-row particle packaging machine can reach more than 1000 bags / minute.

IV. Operation steps of multi-row particle packaging machine

The operation steps of the multi-row particle packaging machine are as follows:

1. Put granular objects into the hopper.

two。 Adjust the capacity of the metering cup to ensure that the number of granular items in each bag is the same.

3. Adjust the size and shape of the bag.

4. Turn on the machine and start automatic packaging.

5. Check whether the bag is properly sealed and deal with any problems in time.

6. Clean the machine to ensure the cleanliness of the packaging.

V. conclusion

To sum up, the multi-row particle packaging machine is a kind of efficient, accurate, hygienic and labor-saving automatic packaging machine. Its packaging capacity depends on many factors, but it can generally reach about 300-500 bags / minute. In the future development, multi-row particle packaging machine will become more and more popular and become an important equipment in the food packaging industry.