Nbsp;nbsp;nbsp; in today’s rapidly developing industrial era, productivity is the core goal pursued by all factories. As a representative innovative equipment, carton bagging machine can not only accelerate production and improve efficiency, but also has the advantages of convenience and high intelligence, so it is widely used in various fields. This article will introduce the carton bagging machine in detail from the basic structure, manufacturing principle, application scope and future development direction of the machine, which will take you into the world of the future factory.

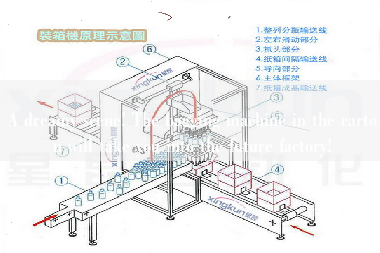

As a kind of high-tech equipment, nbsp;nbsp;nbsp; carton inner bagging machine needs a variety of tiny parts. Its structure mainly includes: machine frame, transmission system, control system, forming system and transportation system and so on. Among them, the machine frame is made of stable steel material, full of toughness and stability, which provides a solid support for the operation of the whole machine. The transmission system is composed of motor, reducer, chain and other components, which can provide a stable power source.

The manufacturing principle of nbsp;nbsp;nbsp; carton bagging machine is mainly divided into three parts: cardboard forming, bag making, and bag packing. Among them, the cardboard forming module is generally composed of high-strength formwork, rollers and pressing rollers, which can process the flat cardboard into the three-dimensional frame needed for bagging. The bag making module is mainly composed of cutting tool holder, transmission device, clapping board and so on, which can realize seamless automatic bag making. The bag packing module can simplify the manual packing operation and improve the production speed and efficiency.

Nbsp;nbsp;nbsp; carton bagging machine is widely used, for example, it can be used in all kinds of carton bagging, such as milk, fruit juice, beverage, and even seafood packaging. In addition, it can also be used for bagging small products such as cosmetics and pharmaceuticals. Many factories put such machines on the production line to reduce labor costs and improve work efficiency and productivity.

In the future development direction of nbsp;nbsp;nbsp;, the carton bagging machine is not only intelligent, but also has further improvement in performance, scale, efficiency and so on. With the development and application of artificial intelligence technology, the future carton bagging machine will be more intelligent and can automatically complete packaging, handling and other work through computers, which will not only further improve production efficiency, but also reduce labor costs.

Nbsp;nbsp;nbsp; in a word, as one of the representatives of industrial automation, the role of carton bagging machine can not be ignored. It has great advantages in production efficiency, automation, labor cost and production quality, and has a very broad application prospect in the future development.