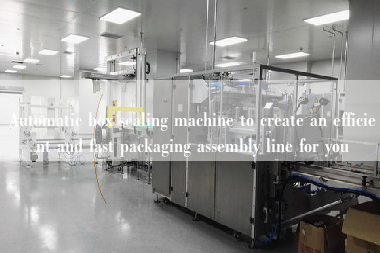

Nbsp;nbsp;nbsp; automatic box sealing machine to create an efficient and fast packaging line for you.

The modern production process of nbsp;nbsp;nbsp; needs the support of automation equipment, and the automatic box sealing machine is one of the key equipment that can improve efficiency and production quality. The automatic sealing machine can quickly complete the sealing and packaging operation, providing efficient, reliable and stable packaging assembly line support for the production line.

Functions and features of nbsp;nbsp;nbsp; automatic box sealing machine

Nbsp;nbsp;nbsp; automatic sealing machine is a kind of efficient packaging equipment, which is used to automatically complete many operations such as sealing, packaging and labeling. It can adapt to different shapes and sizes of packaging boxes, and provide efficient packaging solutions for the production line. Its main features are as follows:

Nbsp;nbsp;nbsp;1. High-speed performance: the working speed of the automatic box sealing machine is fast, and it can complete a large number of box sealing work in a short time, which greatly improves the production efficiency.

Nbsp;nbsp;nbsp;2. Precision: the sealing operation can be realized by programming, which makes the location and quality of the sealing very accurate, and can achieve high-quality sealing effect.

Nbsp;nbsp;nbsp;3. Portability and security: the machine is small, easy to move, simple and safe to operate, which effectively reduces the labor and time cost of sealing operation.

Nbsp;nbsp;nbsp;4. Stability: the automatic box sealing machine can keep the sealing accuracy stable, and it is not easy to cause problems such as box drop or product impact.

Nbsp;nbsp;nbsp;5. Cost saving: through automation technology, we can effectively reduce the cost of manpower, material resources and time, reduce the production cost and improve the production efficiency.

Application of nbsp;nbsp;nbsp; automatic box sealing machine

Nbsp;nbsp;nbsp; automatic box sealing machine is widely used in food, cosmetics, alcohol, medicine, daily necessities, electronics, communications and other industries. In the production line, the automatic sealing machine is a very important equipment, it can completely replace the manual packaging operation, and provide a reliable sealing solution for the production line.

Nbsp;nbsp;nbsp;1. Food industry: the food production process requires that the equipment should meet the strict hygiene and food safety requirements. The automatic box sealing machine can automatically complete the sealing and testing on the conveyor belt to ensure product quality and food hygiene and safety.

Nbsp;nbsp;nbsp;2. Cosmetic industry: automatic box sealing machine can accurately seal and package cosmetic packaging, effectively prevent product leakage and packaging deformation, and make product quality more stable.

Nbsp;nbsp;nbsp;3. Wine industry: high-speed automatic sealing machine can quickly complete the sealing of alcohol products, with good packaging quality, convenient operation and high production efficiency, which effectively solves the problem of low efficiency and high cost of traditional sealing methods.

Nbsp;nbsp;nbsp;4. Pharmaceutical industry: the automatic box sealing machine can carry out good packaging of pharmaceutical products, provide stable, efficient and reliable sealing and packaging solutions for the production line, and reduce the deformation and dampness of pharmaceutical products.

Nbsp;nbsp;nbsp;5. Electronic and communication industry: automatic sealing machine is suitable for the packaging of different types of small or large electronic products, providing efficient and flexible sealing solutions, which helps the production line to improve work efficiency and production capacity.

Operation and matters needing attention of nbsp;nbsp;nbsp; automatic box sealing machine

Nbsp;nbsp;nbsp; in order to ensure the effectiveness of the automatic box sealing machine, we must follow the correct operation procedures and matters needing attention.

Nbsp;nbsp;nbsp;1. Before operating the automatic box sealing machine, you should check whether the machine is normal and make sure that there are no foreign bodies or other obstacles before the machine is running.

Nbsp;nbsp;nbsp;2. When using the automatic box sealing machine or replacing the equipment, it is necessary to train or learn the equipment to ensure that the equipment is operated correctly.

Nbsp;nbsp;nbsp;3. The automatic box sealing machine should be maintained and maintained regularly to check whether the key parts need to be replaced and keep the machine in good condition.

Nbsp;nbsp;nbsp;4. In the process of production operation, operators should pay close attention to the working status of the automatic sealing machine. If there is anything abnormal, they should stop the machine in time and contact the engineer for maintenance.

Nbsp;nbsp;nbsp;5. When using automatic packing machine for packaging, the corresponding packaging materials should be used to ensure the quality assurance of sealing and packaging.

Nbsp;nbsp;nbsp; conclusion

Nbsp;nbsp;nbsp; automatic box sealing machine is one of the indispensable equipment in modern production line. It can quickly and accurately provide efficient and reliable sealing and packaging solutions for various industries, improve production efficiency, reduce production costs, and are favored by many enterprises. Through correct operation and matters needing attention, we can optimize the efficiency of the automatic box sealing machine, ensure the normal operation of the production line, and significantly improve the production efficiency.