Nbsp;nbsp;nbsp; (Note: this article aims to demonstrate the advantages of intelligent palletizers and its application in building efficient production lines, as well as how it makes production more leisurely. )

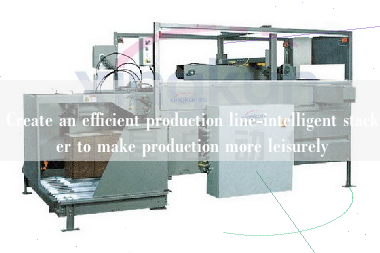

Nbsp;nbsp;nbsp; in modern industrial production, the emergence of automatic production line has become a well-deserved trend. In order to achieve higher production efficiency and enable enterprises to complete tasks more quickly and efficiently, intelligent palletizer came into being. It can help enterprises to build efficient production lines and make the production process more leisurely.

Nbsp;nbsp;nbsp; intelligent palletizer, also known as automatic palletizer, is a highly intelligent closed storage and processing unit. It creates a fully automated stacking system by using advanced computer vision and machine learning algorithms. It has a wide range of applications and can deal with a variety of differentiated products needed on the production lines of food, beverage, pharmaceutical, chemical and electronics industries.

Nbsp;nbsp;nbsp;, what is the difference between intelligent palletizers and traditional palletizers? First of all, the intelligent palletizer has a faster and more efficient speed, and can complete the task of stacking goods in a very short time. Secondly, intelligent palletizer can save a lot of human resources for enterprises, because the operation process is completely automatic and almost no human intervention is needed. In addition, the error rate of intelligent palletizer is very low, which can ensure the quality of products and reduce the production cost of enterprises.

Nbsp;nbsp;nbsp; intelligent palletizer can help enterprises to build efficient production lines. Because it can increase productivity, improve security and reduce costs. Through the intelligent palletizer, the enterprise can be liberated from the tedious and high-intensity manual operation, reduce the burden of the staff, and focus more on the technical and management work. This can help enterprises to better achieve production goals and gradually build efficient production lines.

Nbsp;nbsp;nbsp; in addition, intelligent palletizer can also help enterprises to manage inventory more effectively. Because of its computer vision and machine learning functions, intelligent palletizer can track and manage inventory in real time, so that enterprises can better understand the situation of inventory. Especially in the food and pharmaceutical industries, intelligent palletizer plays a very important role in the strict management of product shelf life.

Nbsp;nbsp;nbsp; of course, smart palletizers also have some challenges to overcome. One of the biggest challenges is the technical difficulties. Because intelligent palletizer needs a high level of computer vision and machine learning technology, its research and development requires high professional skills and a lot of time and resources.

Nbsp;nbsp;nbsp;, however, despite some technical problems, the advantages of intelligent palletizers are still very significant. Through the use of intelligent palletizer, enterprises can achieve higher production efficiency, more effective inventory management, reduce the work intensity of employees, and improve the quality of products. These advantages make the intelligent palletizer a good helper for enterprises to build efficient production lines.

Nbsp;nbsp;nbsp; is very important to build an efficient production line in a modern business environment. Compared with the traditional production line which varies from person to person, the emergence of intelligent palletizer provides a reassuring and efficient alternative for enterprises. When intelligent palletizers appear in the production line, the production efficiency of enterprises will be greatly improved, so as to achieve their own production goals more quickly.