Do you know? This printing and bagging machine automatic bagging factory has unexpectedly realized fully automated production!

In the modern industrial production, automatic production has become a trend. More and more enterprises begin to introduce automatic production lines to improve production efficiency and reduce costs. Today, I would like to introduce this automatic packaging factory of printing and bagging machine, which is a good example.

The factory, located in a small city in southern China, was established in 2010. At that time, it was just a small workshop, mainly producing some simple plastic bags. However, with the continuous expansion of the market, it has gradually developed and become a leading local enterprise.

In 2015, the factory introduced an automatic production line for the production of automatic packaging bags for printing and bagging machines. With the input of this production line, the production efficiency of the factory has been greatly improved. After that, the factory introduced a number of automatic production lines one after another to achieve fully automated production.

So how does this factory achieve fully automated production? Next, let’s take a closer look at it.

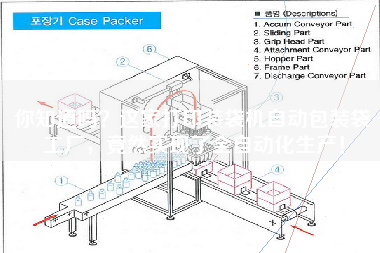

I. composition of automatic production line

This automatic production line is mainly composed of the following parts:

1. Printer: used to print patterns and text on bags.

two。 Cutting machine: used to cut printed bags to the required size.

3. Bagging machine: used for automatic bagging of cut bags.

4. Sealing machine: used to seal packed bags.

5. Automatic conveyor belt: used to automatically transport sealed bags to the next process.

2. Work flow of automatic production line

The workflow of this automatic production line is as follows:

1. The printer prints the desired patterns and text on the bag.

two。 The cutting machine cuts the printed bags to the desired size.

3. The bagging machine automatically packs the cut bags.

4. The sealing machine seals the packed bags.

5. The automatic conveyor belt automatically transports the sealed bags to the next process.

III. Advantages of automatic production line

The main advantages of this automatic production line are as follows:

1. High production efficiency: the production efficiency of automatic production line is much higher than that of manual production, which can greatly improve production efficiency.

two。 Stable product quality: the automatic production line can ensure the stability of product quality and reduce the instability of product quality caused by improper human operation.

3. Cost reduction: automatic production line can reduce labor costs and production costs.

4. Reduce labor intensity: automatic production line can reduce the labor intensity of workers and improve the comfort of the working environment.

IV. Conclusion

The above is the introduction of fully automated production in this automatic packaging factory of printing and bagging machine. It can be seen that the automatic production line has very significant advantages in improving production efficiency, reducing cost, stabilizing product quality and so on. It is believed that with the continuous progress of science and technology, the automatic production line will be applied in more and more fields.