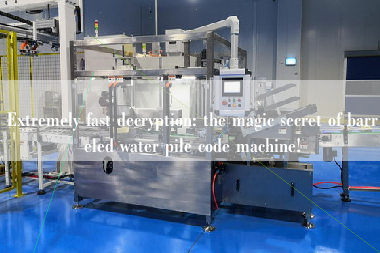

The nbsp;nbsp;nbsp; barreled water stack machine is an amazing machine that can stack hundreds of barreled water neatly and orderly in a short time to make it easier to store and sell. What is the working principle of this machine, and what are its advantages and disadvantages? In this article, we will uncover the magic secret of the barreled water reactor machine and explain how this machine works and why this technology deserves our attention.

Nbsp;nbsp;nbsp; first of all, let’s take a look at how the barreled water stack code machine works. This kind of machine uses automation technology and can quickly organize and pile up large amounts of bottled water. It usually consists of a grab manipulator, a conveyor belt and a weighing system. First, the robot arm takes buckets of water from the conveyor belt in batches and puts them on the weighing system to weigh them. Then, the robot arm will remove the barreled water with a certain weight and stack it in accordance with the requirements of the procedure, so as to better maintain the logistics efficiency. An automated process like this can accomplish a lot of work quickly, reduce labor costs and improve efficiency.

Nbsp;nbsp;nbsp; secondly, what are the advantages of barreled water stacking machine? First of all, the barreled water stack machine can quickly deal with a large amount of barreled water, which can improve productivity and efficiency. Secondly, the machine can weigh and stack automatically, reducing human errors and delays in the processing process. Finally, the machine can reduce the use of manpower in the process of processing, which greatly reduces the labor cost. In a word, the barreled water pile code machine is a very practical and efficient automatic machine.

Nbsp;nbsp;nbsp;, however, the barreled water stack code machine also has some disadvantages. First of all, the cost of the machine is relatively high, requiring a lot of investment in order to purchase and maintain. Secondly, the machine needs professional technical personnel for operation and maintenance, if not properly, it will lead to machine problems. Finally, the service life and maintenance cycle of the machine also takes a long time, which requires frequent repair and maintenance, which increases the maintenance cost and time.

Nbsp;nbsp;nbsp; is more and more widely used in modern logistics and manufacturing, because they can improve productivity and efficiency, reduce tedious work and labor costs. Barreled water stack machine, as one of the representatives of automatic machines, is also widely used at home and abroad. The emergence of it not only changes the mode of production and logistics management of the barreled water industry, improves production efficiency, but also brings better development opportunities for the industry.

Nbsp;nbsp;nbsp; in short, barreled water stacking machine is a magical machine, which can deal with large amounts of barreled water quickly and effectively. Its working principle, advantages and disadvantages all need us to deeply understand and master in order to better apply and apply this technology. Barreled water stacking machine has a broad development prospect in both industrial application and logistics management, which will help to promote the development of automatic manufacturing and intelligent logistics in our country.