In modern manufacturing, the importance of product identification is self-evident. A good product logo can not only make it easier for consumers to identify products, but also increase brand awareness and reputation. The hot melt adhesive labeling technology is a way to make the product logo more solid and durable. This article will introduce the operation steps and advantages of hot melt adhesive labeling technology in detail.

1. Operation steps of hot melt adhesive labeling technology

1. Preparatory work

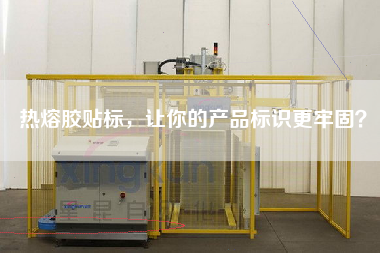

Before carrying out hot melt adhesive labeling, you need to prepare the corresponding equipment and materials. In terms of equipment, a hot melt adhesive labeling machine, a printing press and a die-cutting machine are needed. Materials, the need for hot-melt adhesive label paper, hot-melt adhesive, ink, die-cutting knife and so on.

two。 Printing

Print the products that need to be labelled. When printing, we need to pay attention to the choice of ink and the quality of printing to ensure the clarity and aesthetics of the logo.

3. Die cutting

Die-cutting the printed logo. In die-cutting, attention should be paid to the accuracy and speed of die-cutting to ensure the accuracy of the size and shape of the logo.

4. Hot melt adhesive labeling

The die-cut logo is labelled through the hot melt adhesive labeling machine. When labeling, you need to pay attention to the temperature and viscosity of the hot melt adhesive to ensure that the logo can be firmly attached to the product.

II. Advantages of hot melt adhesive labeling technology

1. Firm and durable

Hot melt adhesive labeling technology can make the logo more solid and not easy to fall off. This is because the hot melt adhesive can form a chemical bond with the product surface when labeling, thus increasing the adhesion and durability of the label.

two。 Beautiful and generous

Hot melt adhesive labeling technology can make the logo more beautiful and generous. This is because the hot melt adhesive can be completely attached to the product surface, there will be no bubbles, wrinkles and other problems, so as to improve the aesthetics of the logo.

3. A wide range of application

Hot melt adhesive labeling technology is suitable for products of various materials, such as plastic, glass, metal and so on. This is because the hot melt adhesive can form strong chemical bonds with various materials, thus increasing the adhesion and durability of the logo.

In short, hot melt adhesive labeling technology is a way to make the product logo more solid, durable and beautiful. When using hot melt adhesive labeling technology, you need to pay attention to the operation steps and the temperature and viscosity of the hot melt adhesive to ensure that the label can be firmly attached to the product.