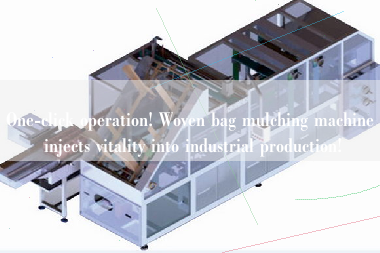

Nbsp;nbsp;nbsp; woven bag mulching machine injects vitality into industrial production!

Nbsp;nbsp;nbsp; in the current era, with the continuous progress of science and technology, industrial production continues to develop and improve. Among them, the woven bag mulching machine, as one of the important equipment in the industrial production process, has been paid more and more attention. It can inject vitality into industrial production and make production faster, more efficient and safer. What is this device? What are the advantages? Let’s answer them one by one.

What is the nbsp;nbsp;nbsp; woven bag mulching machine?

The full name of nbsp;nbsp;nbsp; woven bag covering machine is “woven bag whole machine covering machine”, which aims to provide convenient and fast processing conditions for woven bag processing and production. At first, the processing method of woven bag production is sewing by hand, which is time-consuming, laborious and expensive. After years of research and development and improvement, woven bag mulching machine came into being and become an important tool to improve production efficiency and reduce costs.

What are the advantages of nbsp;nbsp;nbsp;?

Nbsp;nbsp;nbsp;1. Reduce labor costs.

The traditional sewing method of nbsp;nbsp;nbsp; woven bag requires a lot of manual operation, which costs a lot of manpower. The use of woven bag mulching machine can greatly reduce the manual operation time, reduce the labor cost and improve the production efficiency.

Nbsp;nbsp;nbsp;2. Save raw materials.

Nbsp;nbsp;nbsp; braided bag covering machine adopts fast covering technology, which effectively reduces the loss of woven bag and saves the use of raw materials. In the traditional mode of production of woven bags, due to the high demand for sewing, there is a lot of waste of raw materials.

Nbsp;nbsp;nbsp;3. Improve production efficiency.

Nbsp;nbsp;nbsp; in the traditional woven bag production mode, due to the need for a large number of manual operation, the production efficiency is relatively low. The advent of the woven bag mulching machine improves the speed and efficiency of processing and production, and greatly shortens the cycle of the production line.

Nbsp;nbsp;nbsp;4. The processing technology is more efficient and accurate.

Nbsp;nbsp;nbsp; braided bag mulching machine adopts advanced technology in the processing process, which can accurately control the processing quality and size. This has a great advantage in the traditional mode of woven bag production, and improves the quality and grade of the products.

Nbsp;nbsp;nbsp;5. The operation is simple and convenient.

The operation of nbsp;nbsp;nbsp; woven bag mulching machine is very simple, and the requirements for operators are not high. This is equivalent to shortening the training time of operators and reducing operating costs.

Application of nbsp;nbsp;nbsp; woven bag mulching Machine in Industrial production

As a kind of industrial production and processing equipment, nbsp;nbsp;nbsp; woven bag mulching machine is widely used in food, chemical, pharmaceutical, daily chemical, building materials and other industries. In the food industry, woven bag mulching machine is mainly used in the production of mesh bags, paper-plastic composite bags and all kinds of food packaging bags; in the chemical industry, it is mainly used in the production of acid and alkali, corrosion resistance industries such as woven bags, non-woven bags, and packaging of dangerous goods; and in pharmaceutical, daily chemical, building materials and other industries, woven bag film mulching machine also plays an important role, such as the packaging of new building materials, cement, chemical fertilizer and other products.

Nbsp;nbsp;nbsp; in a word, as one of the important members of modern industrial production equipment, woven bag mulching machine has brought a lot of convenience and benefits to industrial production. As enterprises and individuals, when purchasing, we should choose products of reliable quality and stable performance, fully mobilize its role, and inject more vitality into production.