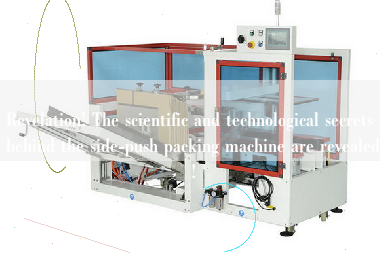

Nbsp;nbsp;nbsp; in recent years, with the development of industry, a variety of automation equipment has been more and more used in the manufacturing process. Among them, side-push packing machine is widely used in express delivery, logistics, food and other industries. So, what kind of scientific and technological secrets are hidden behind these efficient packing machines?

Nbsp;nbsp;nbsp; side-push packing machine mainly uses side-push packing technology, the so-called side-push, means that in the process of packing, the box is pushed from the side instead of falling directly from above. What are the benefits of this design? First of all, it can make the packing process more stable and avoid the product damage caused by the box falling. Secondly, because the box is pushed from the side, manual intervention can be reduced and production efficiency can be improved.

Nbsp;nbsp;nbsp;, however, side-push packing technology is not a simple design, it needs to rely on the cooperation of many technical aspects in order to achieve an efficient and accurate packing process. In addition to conventional mechanical design and electrical control, it also involves many aspects, such as software system, sensor technology and so on.

Nbsp;nbsp;nbsp; first of all, the development of software system is very important. Because the side push packing machine needs to accurately measure the size, weight, shape and other parameters of the box, it needs to be supported by a powerful software system. In the aspect of software design, the adaptability of the packing machine needs to be taken into account. In other words, the packing machine needs to be able to automatically adjust the packing mode according to the different parameters of the box in order to achieve the best packing results.

Nbsp;nbsp;nbsp; secondly, sensor technology is also the key. The sensor is the key component to ensure that the packing machine can accurately sense the location, size, shape and other parameters of the box. The sensor of the packing machine needs to be able to respond to small box changes and has the characteristics of high precision and high reliability.

Nbsp;nbsp;nbsp;, of course, human intervention is also inevitable. However, the design of modern side-push packing machine has reduced the human intervention to a minimum. For example, the operator only needs to put the box away before the packing machine starts, and the rest of the work is done by the packing machine itself. This not only reduces the labor cost, but also greatly improves the packing efficiency.

Nbsp;nbsp;nbsp; in addition to machinery, software, sensor technology and other aspects of cooperation, there is a very important element, that is the structural design of the packing machine. The side-push packing machine needs to complete many tasks in as little space as possible, so it is difficult to design the structure. If the structure design is unreasonable, it will not only reduce the packing efficiency, but also lead to machine failure and other problems.

Nbsp;nbsp;nbsp; to sum up, behind the side-push packing machine, there are a number of scientific and technological secrets. From machinery, software, sensor technology to structural design, we need to focus on consideration and comprehensive cooperation in order to achieve an efficient and accurate packing process. It can be said that the comprehensive application of side-push packing machine has not only promoted the progress of the manufacturing industry, but also laid a solid foundation for the rapid development of express delivery, logistics and other fields.