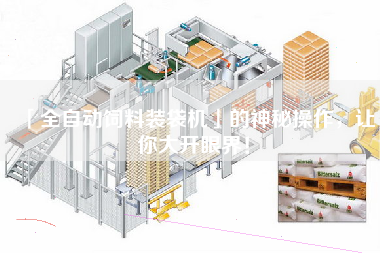

Automatic feed bagging machine is a kind of efficient and intelligent packaging machinery, which can automatically complete a series of operations such as feed measurement, packaging and sealing, which greatly improves the efficiency and quality of feed packaging. However, for many people, the operation of the automatic feed bagging machine is still quite mysterious. Today, let’s take a look at the operation steps and skills of this machine.

I. preparatory work

Before using the fully automatic feed bagging machine, some preparatory work needs to be done, including cleaning, inspection and debugging. First of all, the residue and dirt inside and outside the machine should be cleaned to ensure the cleanliness and hygiene of the machine. Secondly, it is necessary to check whether the parts of the machine are in good condition, such as conveyor belt, meter, sealer, etc., to ensure the normal operation of the machine. Finally, to debug, according to the need to set the measurement accuracy, packaging speed, sealing temperature and other parameters to meet different packaging requirements.

II. Operation steps

1. Put the feed into the hopper and start the machine. Automatic feed bagging machine will automatically measure and pack the feed into the bag.

two。 By adjusting the speed of the conveyor belt, the speed and efficiency of packaging can be controlled. In general, the speed of the conveyor belt should match the speed of the meter to ensure accurate measurement and packaging of feed.

3. In the packaging process, it is necessary to constantly check the running status and packaging effect of the machine, such as whether there is leakage, sealing, air leakage and so on. If problems are found, the machine should be stopped for maintenance in time to ensure the normal operation of the machine and the quality of packaging.

4. After the packing is finished, put the bag into the sealer and seal it. In the sealing process, it is necessary to control the sealing temperature and pressure to ensure that the sealing is firm and beautiful.

5. Finally, the packaged feed bag is fed into the conveyor belt for further processing, such as printing labels, palletizing, packing and so on.

Skills and matters needing attention

1. Before using the fully automatic feed bagging machine, you need to read the instructions carefully and conduct relevant training and learning to ensure that the operation is correct and safe.

two。 In the process of packaging, attention should be paid to controlling the flow and distribution of feed to ensure accurate measurement and uniform packaging.

3. In the sealing process, we need to pay attention to control the sealing temperature and pressure to ensure that the sealing is firm and beautiful. At the same time, attention should be paid to avoid the leakage of feed at the seal.

4. In the course of operation, attention should be paid to keeping the machine clean and hygienic, and regular cleaning and maintenance should be carried out to prolong the service life of the machine and ensure the quality of packaging.

In a word, the full-automatic feed bagging machine is an efficient and intelligent packaging machine, and its operation steps and skills are not mysterious. As long as we master the correct methods and matters needing attention, we can easily complete the packaging and sealing of feed. I hope this article can be helpful to you, so that you can better understand and use the full-automatic feed bag machine.