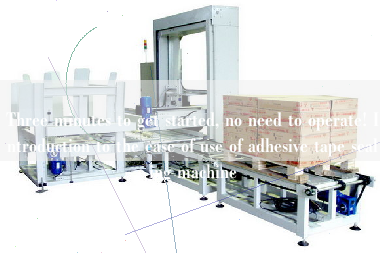

In the modern production and operation of nbsp;nbsp;nbsp;, tape sealing machine has become one of the common equipment in enterprises. The machine is a tool for quickly and effectively sealing cartons by using adhesive tape. However, some users may think that using a tape sealing machine requires a long learning curve and complex maintenance details. Then, this article will give you a detailed introduction to the ease of use of tape sealing machine and how to get started in a short time.

Nbsp;nbsp;nbsp; first of all, it is worth noting that there are many kinds of tape sealing machines. According to the function, we can divide it into manual and automatic. In the process of use, the manual sealing machine requires the operator to apply its own force, while the automatic sealing machine can complete the sealing process by itself through the motor.

Nbsp;nbsp;nbsp; well, for novice users, we recommend the purchase of automatic box sealing machine. The use of automatic box sealing machine can improve efficiency and reduce tedious operation steps in the near future. Just push the carton to the sealing machine, press the sealing key, and the machine can automatically perform the follow-up operation. The device can also automatically recognize dimensions, so there is no need for manual adjustment.

Compared with nbsp;nbsp;nbsp;, manual sealing machine requires more physical strength and operation skills, resulting in lower sealing efficiency and more time and energy consumption. Novice users also need to master the right skills to ensure correct operation. If the size of the carton is not the same, the parts on the machine need to be manually adjusted before cutting and sealing. These additional operations may challenge the operational ability of beginners and lead to inadequate package security during transportation.

With the continuous development of production and operation of nbsp;nbsp;nbsp;, the application of automatic box sealing machine has covered packaging, logistics, express delivery and other industries, and has been widely used. Compared with manual sealing machine, its advantage lies in reliability, efficiency and autonomy, so it is suitable for mass production and express parcel delivery.

In addition to the types of nbsp;nbsp;nbsp;, novice users also need to pay attention to the maintenance of the tape sealing machine. It requires frequent cleaning and maintenance to ensure smooth operation. First of all, the machine needs to clean its surface and internal components frequently. Cleaning it can prevent the tape from sticking or getting stuck, which leads to the failure of sealing. Second, the machine needs to check the status of its components and parts frequently. These components include cutters and gears, which should be replaced or repaired in time if damage or wear occurs. Finally, if the machine is found to be malfunctioning or improperly used, it should also be handed over to professional and technical personnel in time to troubleshoot the problem.

Nbsp;nbsp;nbsp; after beginners understand the ease of use and maintenance of the tape sealing machine, they also need to carefully read the user manual provided by the manufacturer. This manual will be an important tool to guide you to use the machine correctly. It provides detailed steps, skills and maintenance methods, so that you can quickly get started with the tape sealing machine.

Nbsp;nbsp;nbsp; to sum up, as an important equipment of the enterprise, tape sealing machine provides convenience for production and logistics. As a novice user, choosing automatic box sealing machine can improve the efficiency of box sealing and reduce the difficulty of operation. Regular cleaning and maintenance of the machine is also helpful to its normal operation. Finally, reading the user manual is the key to getting started quickly. I hope this article can help you better use and maintain the tape sealing machine.