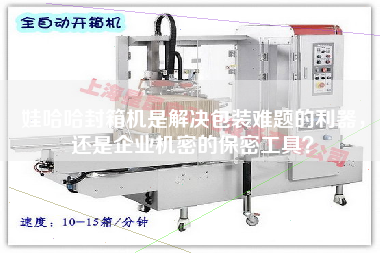

In recent years, with the rise of e-commerce, the logistics industry has also been greatly developed. In the logistics industry, packaging has always been a more important link. In order to improve the efficiency of packaging, many enterprises begin to use automatic sealing machine to seal boxes. Among them, Wa sealing machine is a kind of popular sealing machine. However, many people have some questions about the use of Wa sealing machine, for example: Wa sealing machine is a sharp tool to solve packaging problems, or a secret tool for corporate secrets? This article will give you a detailed introduction to the use of Wa sealing machine and related problems.

I. the use of Wa box sealing machine

1. Preparatory work

Before using the Wa sealing machine, we need to do some preparatory work first. For example, you need to prepare packing tape, boxes, some tools and so on. In addition, some simple debugging of Wa sealing machine is needed.

two。 Debug

When debugging the Wa sealing machine, we need to pay attention to the following points:

(1) first of all, it is necessary to turn on the power supply of the Wa sealing machine and turn on its switch.

(2) then, the sealing belt needs to be loaded into the sealing machine and adjusted to the appropriate position.

(3) then, some simple debugging is needed. For example, the tension of the sealing belt and the speed of the sealing machine need to be adjusted.

3. Seal the box

When the debugging of the Wa sealing machine is completed, you can begin to seal the box. The specific steps are as follows:

(1) first of all, the box needs to be placed on the workbench of the Wa sealing machine and aligned with the sealing mouth of the sealing machine.

(2) then, you need to press the start button of the sealing machine to let the sealing machine start to work.

(3) next, the sealing tape needs to be affixed to the box and pulled out from the other end of the sealing machine.

(4) finally, it is necessary to cut the sealing belt and put the box into logistics and transportation.

Second, the advantages of Wa box sealing machine

1. Improve work efficiency

The use of Wa box sealing machine can greatly improve work efficiency. Compared with manual sealing, Wa sealing machine can complete the sealing work more quickly, thus improving production efficiency.

two。 Reduce labor costs

The use of Wa box sealing machine can reduce labor costs. Compared with manual sealing, Wa sealing machine can reduce manual operation, thus reducing labor costs.

3. Improve the quality of sealing

The use of Wa sealing machine can improve the sealing quality. Compared with manual sealing, Wa sealing machine can paste the sealing belt more evenly, so as to improve the sealing quality.

Third, the shortcomings of Wa box sealing machine

1. The price is higher

Compared with manual sealing, the price of Wa sealing machine is higher, which requires a certain investment cost.

two。 High maintenance cost

Wa sealing machine needs regular maintenance, which will also increase the maintenance cost.

3. Some technical support is needed.

Wa box sealing machine needs some technical support, for some people who do not understand the technology, it may take some time to learn.

IV. Conclusion

To sum up, Wa sealing machine is a very practical sealing tool. It can greatly improve the work efficiency, reduce the labor cost and improve the sealing quality. However, at the same time, there are some shortcomings, such as high price, high maintenance cost and the need for some technical support and so on. Therefore, when choosing whether to use Wa sealing machine or not, we need to judge according to our own actual situation.